Fleet Total

Number of aircraft OOS:

Saved +

Digitizing

Inspections

Revolutionary

Reporting

Financial

Benefits

Data

Collection

Data is collected either manually or automatically

through the

use of a drone.

Digital

Inspection

Automated

Inspection

Manual inspections

using a

digital App

Experts from AkzoNobel use the digital App to store the information collected, such as dry film thickness, color variation, gloss and general appearance, as an Audit Report on an iPad or tablet. The data is then fed back to a database which tracks the fleet's performance over time.

As part of our digital inspection package, you'll also receive:

- Condor full body harness

- BYK Spectro2Guide

- iPad Pro w/ Falcon Heavy Duty Case

- PosiTector 6000 Pro FN3

Inspection Services?

Automated inspections

using drone

technology

Automated inspections are conducted by drones which fly in a set grid over the plane's surface, taking up to 1,000 HD photos.

This standardizes the inspection and is more objective. The drones’ machine learning algorithm analyzes the photos and identifies issues on the paint surface in exactly the same way, every time.

It is also faster and more in-depth than a manual inspection; an automated drone can scan an entire narrowbody aircraft in less than an hour.

Inspection Services?

Real-time Reporting

& Predictive Maintenance

Detailed reports for the here and now and future maintenance scheduling.

Reporting

Data

Predictive Maintenance

Real-time Dashboard

& Data-Driven

Reporting

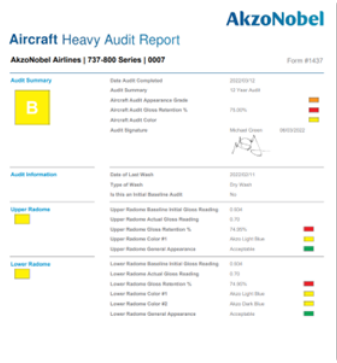

Detailed audit reports

A detailed audit report provides the baseline against which a future paint schedule can be defined. It includes dry film thickness measurements, gloss readings, color and a general appearance rating on all parts of the airplane, from the radome, captain and forward entry through to the fuselage, wings and engines.

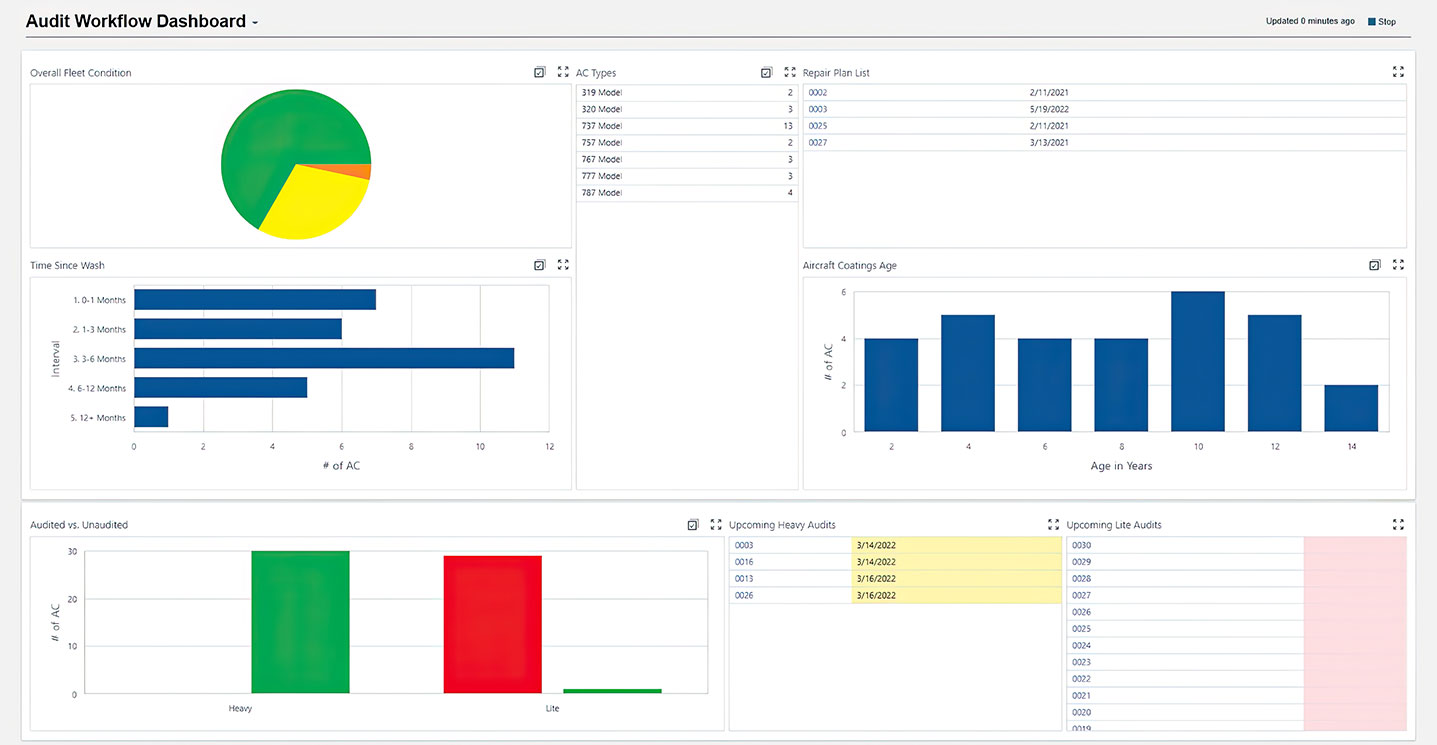

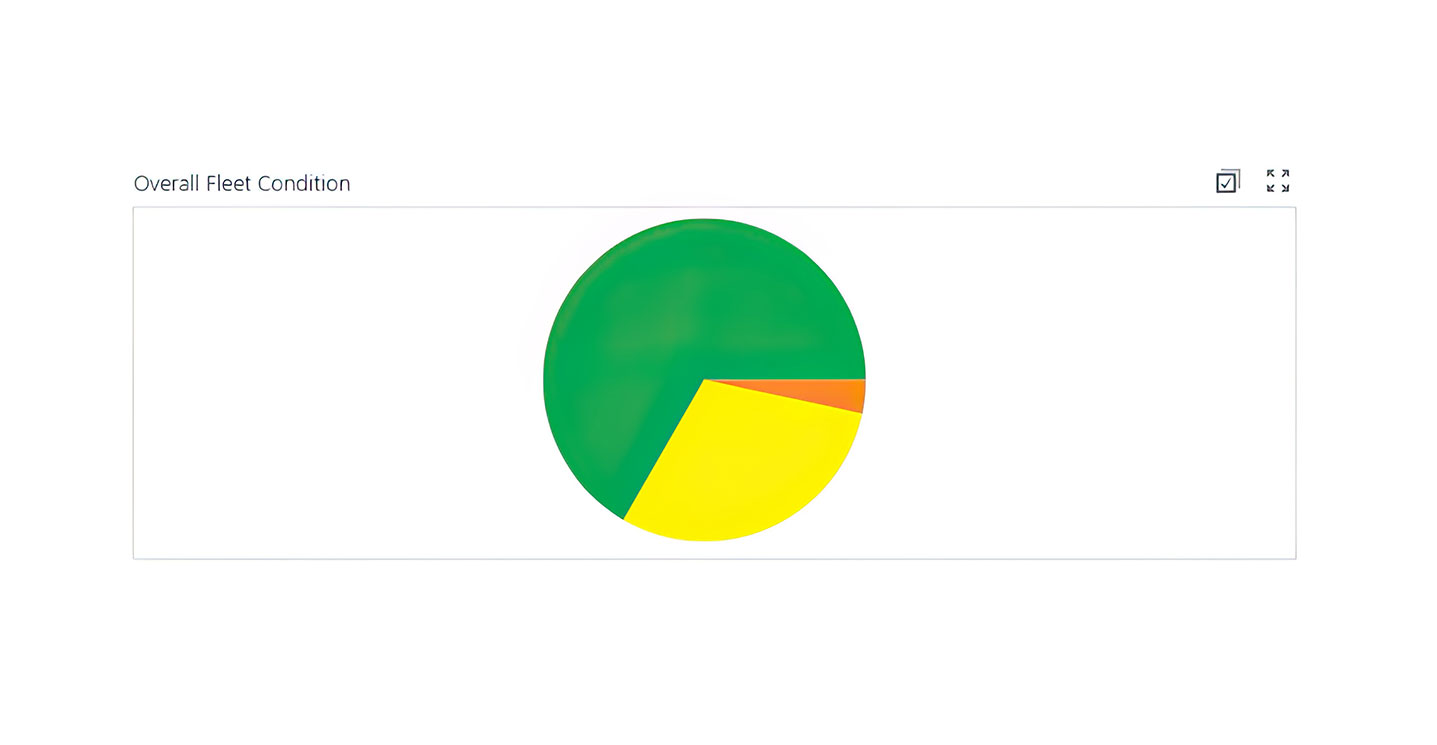

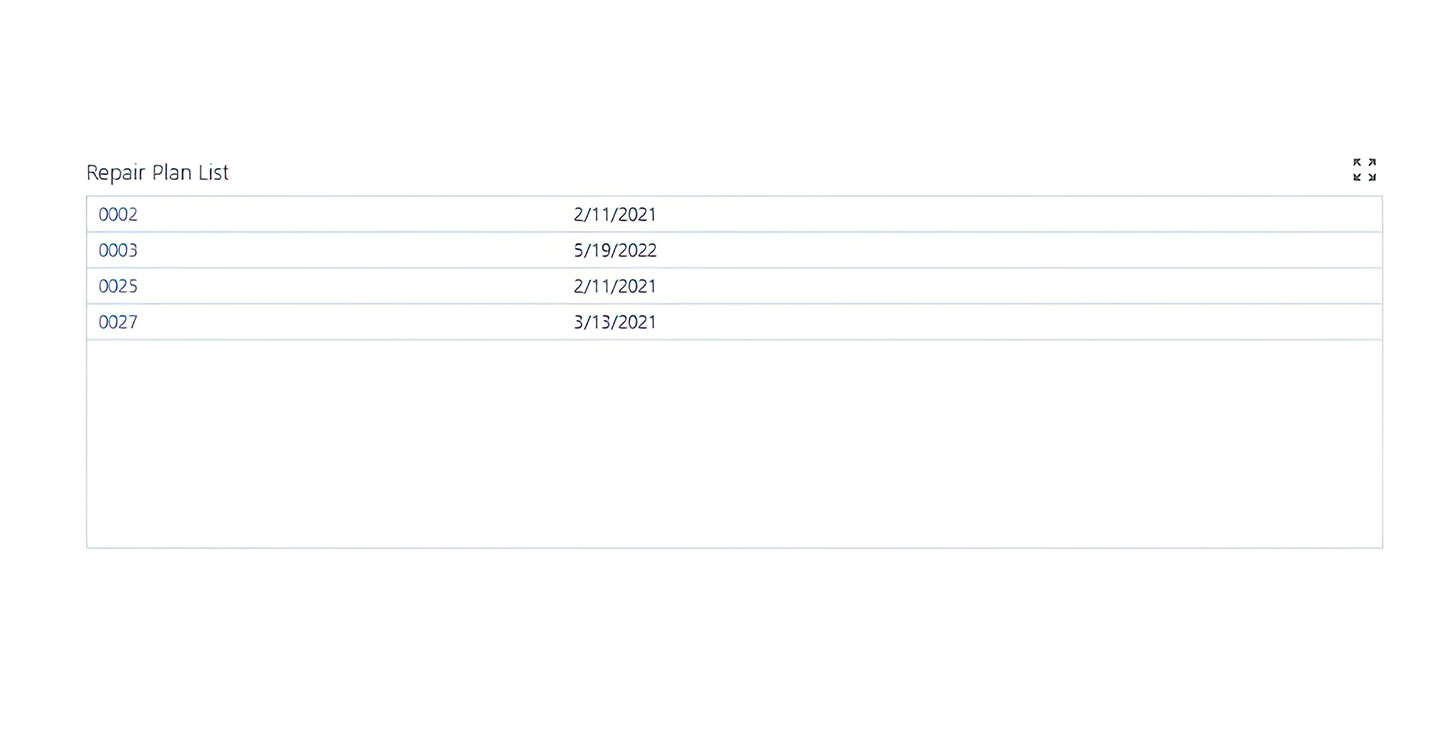

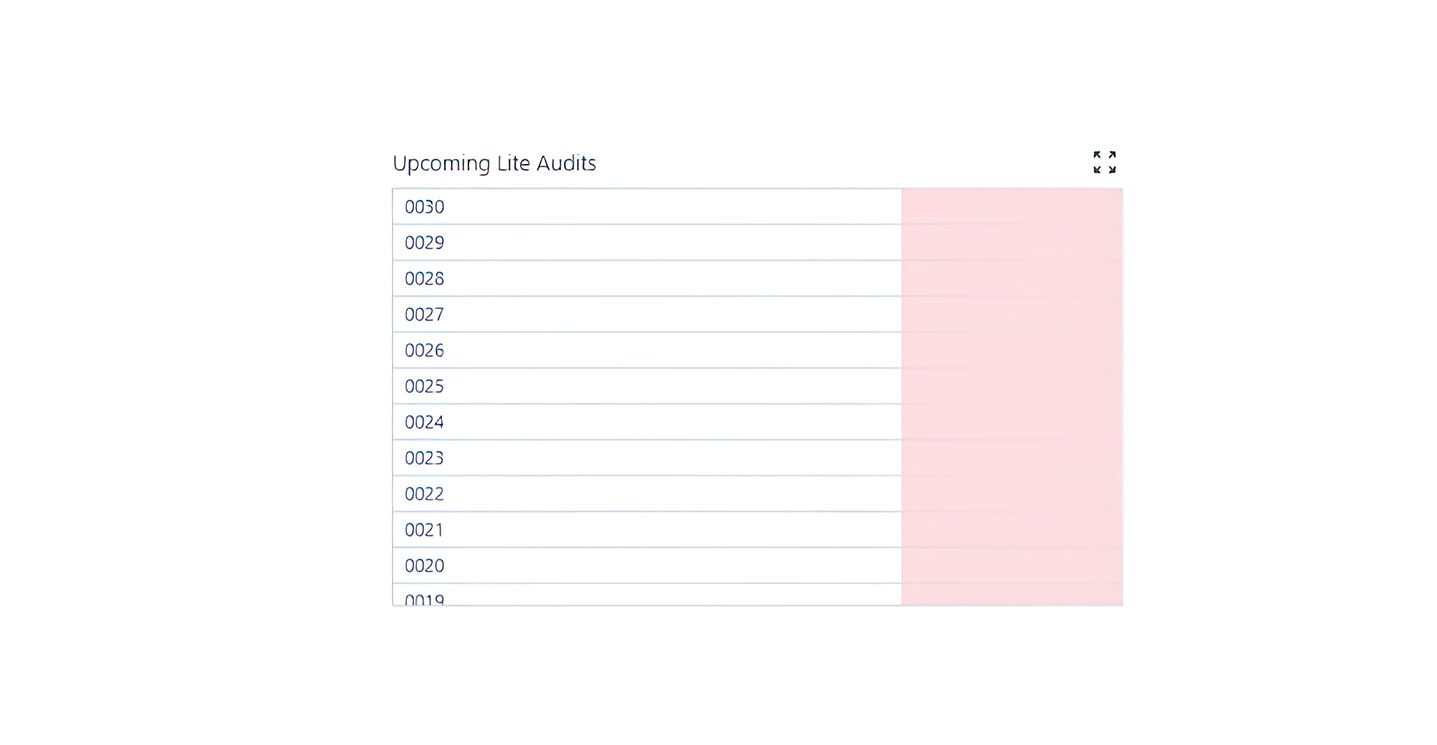

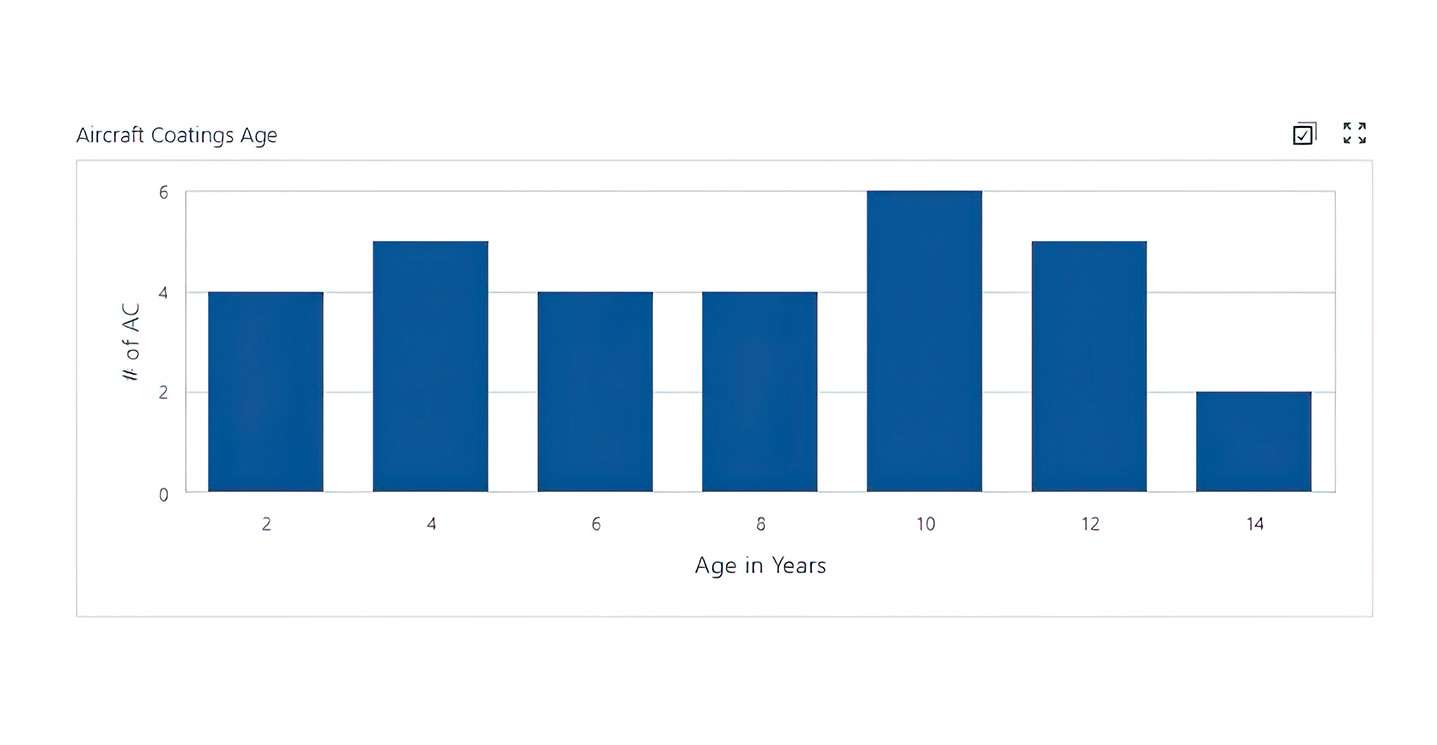

Fleet dashboard

An audit flow dashboard provides an at-a-glance view of the overall fleet condition with specific detail on a coating’s age, upcoming audits and a repair list plan.

Repair reports

A repair report highlights areas of concern where a touch-up or more extensive repair may be required prior to an airplane requiring a full repaint.

Real-time Dashboard

& Data-Driven

Reporting

Fleet data over time

By analyzing this information, and mapping it over time, a more accurate maintenance and repaint schedule can be calculated using quantitative data. It becomes easier and more accurate to determine when an aircraft needs to be repainted, rather than simply using time or flight hours.

Flight data

Schedules can be created that balance the practical performance of a coating and where the aircraft in a fleet are being operated (i.e. the different flight paths, distances, heights, etc.) against the aesthetic/marketing (i.e. branding) and business needs of the airline.

Weather data

Schedules also take into account the environment in which the individual aircraft have been flying, and the potential impact of different climactic conditions on the aircraft coating.

Proactively Manage

Your Repaint Cycle

Multiple Data Sources

Multiple data sources enable you not only to determine when an aircraft needs to be repainted now, but also predict when it will need repainting in the future. By analyzing data across the entire fleet, it can also predict when similar aircraft, with similar coatings and flying similar routes will also need to be repainted.

Model the optimal maintenance cycle

Predictive maintenance allows for aircraft to be on the ground in a more operationally efficient and cost-effective way.

Value Calculator

The proof is in the numbers

Calculate how much you could save based on the size and status of your existing fleet.

Size of fleet

Average Repaint Cost/AC

Average OOS Revenue Loss/AC

Annual Aircraft Repainted

8

Repaint Cost Annually

Out of Service (OOS)

Revenue Loss Annually

Total Cost Annually

Annual Aircraft Repainted

8

Fewer Aircraft Repainted Annually*

Annual Repaint Cost Savings*

Annual OOS Revenue Retention*

Out of Service (OOS) Revenue Loss Annually

OOS Revenue

Loss Annually

Repaint Cost

Annually

* vs. 8 year cycle

Average age of repaint